Concrete Fixing and Resurfacing in North Little Rock, AR

Concrete surfaces in North Little Rock frequently deal with issues like splitting and discoloring due to fluctuating weather and hefty use. These issues can take away from both performance and look. Numerous fixing methods exist to address these problems successfully. Home owners must consider their alternatives very carefully. Understanding the advantages and techniques of concrete repair work can result in enduring improvements. What elements should be taken into consideration before beginning a project?

Usual Concrete Issues in North Little Rock

Concrete surfaces in North Little Rock usually deal with a variety of usual issues that can influence their toughness and look. Cracking is just one of one of the most prevalent troubles, often arising from temperature level changes, settling foundations, or heavy lots. These cracks can expand in time, causing more architectural concession. One more problem is spalling, which occurs when the surface of the concrete starts to flake or chip away, generally due to freeze-thaw cycles or bad drain. Furthermore, efflorescence, a white, grainy deposit, can base on the surface area, suggesting dampness concerns within the concrete. Staining from oil, corrosion, or other materials can likewise diminish the aesthetic charm. Inevitably, surface area wear from foot website traffic and weather condition conditions can lead to a rough texture that is both undesirable and harmful. Attending to these problems without delay is crucial to preserving the stability and aesthetic appeal of concrete surfaces in the area.

Methods of Concrete Repair

The methods of concrete fixing include different methods customized to attend to details concerns. Remarkable strategies include crack injection methods for sealing crevices, resurfacing overlays to revitalize surface areas, and patching techniques for local damage. Each alternative offers distinct benefits that accommodate various repair service requirements and conditions.

Split Injection Methods

Split shot strategies act as effective techniques for fixing damaged concrete, addressing issues such as leaks, architectural stability, and aesthetic problems. This technique entails infusing specialized products, such as epoxy or polyurethane, into cracks to develop a water tight seal and bring back strength. The procedure generally begins with cleansing the crack to eliminate debris and wetness. As soon as prepared, a port is installed at the split's entry, allowing the injection material to move via. legendary concrete north little rock concrete contractor. As the injected substance remedies, it bonds with the surrounding concrete, properly sealing the split and stopping future water seepage. These strategies not just boost the resilience of the concrete yet likewise enhance its appearance, making them a prominent selection for both domestic and commercial applications

Resurfacing Overlays Options

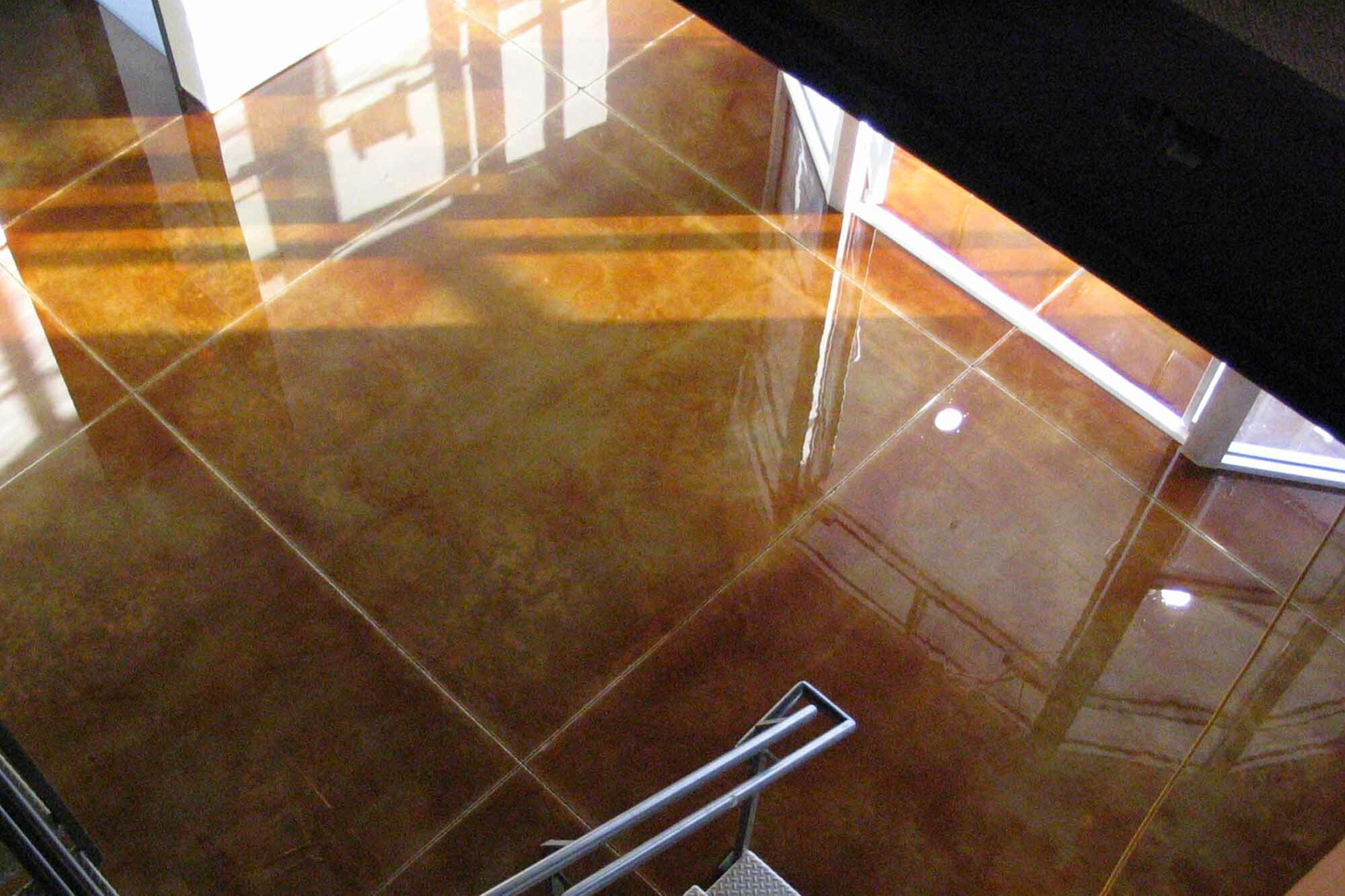

Numerous resurfacing overlay alternatives exist for fixing and rejuvenating used or damaged concrete surfaces. These overlays can enhance both the appearance and sturdiness of concrete, making them a popular choice for business and residential applications. One option is a polymer-modified overlay, which offers versatility and resistance to breaking. An additional is a decorative overlay, available in different shades and appearances, allowing for aesthetic personalization. Additionally, self-leveling overlays are designed for quick application and can develop a smooth, even surface area. Epoxy layers provide a protective layer that is immune to discolorations and chemicals. Stamped overlays can mimic all-natural products like stone or block, including aesthetic charm while providing a durable surface area. Each alternative provides to details demands and conditions.

Patching and Repair Methods

Reliable patching and repair work methods are vital for restoring the honesty of damaged concrete surface areas. Various techniques are utilized based on the extent and kind of damage. For small cracks, epoxy or polyurethane shots can properly secure and avoid more degeneration. Larger cracks and spalling might require a much more significant strategy, making use of concrete patching substances that blend with the existing surface. Additionally, surface fixings may involve grinding or chiseling away damaged locations prior to applying a brand-new concrete layer. For extensive damage, full slab replacement could be required. It is essential to examine the underlying root causes of damages, such as dampness or settling, to ensure long-lasting effectiveness of the fixing techniques utilized, consequently prolonging the life-span of the concrete surface area.

Benefits of Concrete Resurfacing

Concrete resurfacing offers a useful option for bring back the aesthetic and structural integrity of aged or damaged surface areas. This approach not only boosts the appearance of concrete but also extends its life-span, making it a cost-efficient choice for home owners. Resurfacing can effectively eliminate small cracks, imperfections, and staining, providing a fresh, smooth surface that can mimic various structures and shades.

Additionally, it needs much less time and labor compared to complete substitute, decreasing interruption for homeowners or businesses. The process is additionally eco-friendly, as it frequently makes use of recycled materials and decreases waste.

Moreover, resurfaced surfaces can boost grip, making them safer for pedestrians and automobiles. By selecting to resurface, homeowner can attain substantial visual enhancements while making certain the underlying framework stays solid, inevitably improving property worth and curb allure in the future.

Selecting the Right Materials for Your Task

Choosing appropriate materials is crucial for successful concrete fixing and resurfacing tasks. This entails recognizing various sorts of concrete blends, effective surface prep work techniques, and various sealers and coatings alternatives. Each choice can greatly affect the longevity and appearance of the outcome.

Sorts Of Concrete Mixes

Choosing the appropriate concrete mix is crucial for the success of any type of repair or resurfacing project. Numerous sorts of concrete mixes are offered, each tailored to certain needs. For basic repair work, a conventional concrete mix offers durability and toughness, typically including cement, water, gravel, and sand. High-strength mixes, developed for heavy tons, incorporate additional concrete and special ingredients. For decorative surface areas, polymer-modified blends offer boosted adhesion and flexibility, enabling elaborate styles. On the other hand, fast-setting blends are optimal for quick fixings, enabling jobs to proceed without lengthy delays. Self-leveling substances are valuable in resurfacing, producing a smooth surface. Selecting the ideal mix assurances resilient outcomes and meets the job's useful and visual needs.

Surface Area Prep Work Strategies

Reliable surface prep work is crucial to the success of any kind of concrete repair or resurfacing job. Proper techniques guarantee that the new product adheres well to the existing surface, stopping future problems. The primary step normally involves cleaning the concrete to remove dust, oil, and particles, which can jeopardize bonding. Depending upon the problem of the surface, approaches like shot blasting, grinding, or acid etching may be utilized to attain the wanted texture. Additionally, reviewing the stability of the existing concrete is necessary; any kind of fractures or damage should be fixed before resurfacing. Selecting suitable devices and materials for these tasks is important, as they directly affect the toughness and appearance of the ended up project. Mindful interest to surface area prep work lays the structure for lasting outcomes.

Sealers and Finishes Options

A selection of finishes and sealants are available for concrete repair work and resurfacing jobs, each offering distinct benefits customized to particular requirements. Acrylic sealers, for example, offer a shiny coating and are perfect for attractive applications, while permeating sealants supply defense versus moisture and stains without modifying the surface area appearance. Epoxy finishings are an additional choice, recognized for their toughness and resistance to chemicals, making them ideal for high-traffic areas. In addition, polyurethane coatings use adaptability and UV stability, which is helpful for exterior surfaces. legendary concrete north little rock near me. When choosing materials, elements such as designated use, ecological problems, and visual preferences should be taken into consideration. Correct application of these sealants and completes not just boosts the concrete's look however additionally prolongs its life-span and preserves structural honesty

Tips for Maintaining Your Concrete Surfaces

Regular maintenance of concrete surface areas is necessary for extending their lifespan and enhancing their look. House owners ought to begin by on a regular basis cleansing the surfaces to eliminate dirt, gunk, and debris, which can trigger stains and wear and tear. Using a pressure washer can be a reliable method for deep cleansing, but care ought to be required to prevent harming the concrete.

In enhancement, using a legendary concrete north little rock near me sealer every few years helps shield the surface area from wetness penetration and staining. It is additionally a good idea to examine the concrete periodically for fractures or surface damages. Without delay attending to these concerns via repair services can avoid more degeneration.

Additionally, avoiding using harsh chemicals for cleansing is important, as they can weaken the concrete. In locations prone to freezing temperature levels, utilizing non-corrosive de-icing representatives is suggested to stop surface area spalling. Through these upkeep tips, concrete surfaces can stay long lasting and aesthetically appealing for several years to come.

Specialist vs. DIY Concrete Repair service and Resurfacing

When determining in between expert services and DIY strategies for concrete repair work and resurfacing, homeowners need to take into consideration elements such as project intricacy, spending plan, and desired outcomes. Specialist professionals bring competence, specialized devices, and sector knowledge, ensuring high-quality results and compliance with regional guidelines. They can properly handle complex fixings that call for precision and skill.

On the various other hand, do it yourself approaches can be cost-effective for easier jobs, allowing property owners to save cash on labor expenses. Nonetheless, do it yourself fanatics should be prepared to invest time and effort right into study, implementation, and prep work. Errors can cause more complications and expenses down the line.

Eventually, the option between expert solutions and do it yourself depends upon the property owner's experience, project extent, and readiness to embark on prospective dangers. Considering these aspects will aid guarantee a successful concrete repair or resurfacing task that satisfies assumptions and boosts the building's value.

Frequently Asked Questions

Exactly How Lengthy Does Concrete Repair Take in North Little Rock?

Concrete repair commonly takes one to 3 days, depending upon the level of damages and weather. Curing might call for extra time prior to the surface area is fully usable, influencing the overall period of the task.

What Is the Expense of Concrete Resurfacing per Square Foot?

The price of concrete resurfacing generally ranges from $3 to $7 per square foot, relying on aspects such as the problem of the surface, the materials used, and the complexity of the work.

Can I Stroll on Newly Fixed Concrete Promptly?

Walking on newly repaired concrete promptly is generally not recommended (legendary concrete north little rock). A lot of specialists advise waiting at the very least 24 to 48 hours for correct treating, making certain the honesty of the repair work and preventing possible damage or uneven surface areas

Do I Need an Authorization for Concrete Repair Works in North Little Rock?

A permit is usually required for concrete repairs, depending upon the scope and regional guidelines. It is a good idea for house owners to seek advice from the regional building department to validate details needs for their job.

What Weather Condition Conditions Affect Concrete Repair Projects?

Climate problems such as temperature, humidity, and precipitation substantially effect concrete fixing projects. Extreme warmth can cause fast healing, while cool temperatures may reduce it down. Rainfall can compromise the high quality of the repair, requiring mindful preparation.

Numerous resurfacing overlay choices exist for fixing and revitalizing used or broken concrete surfaces. Efficient patching and fixing methods are crucial for bring back the honesty of damaged concrete surfaces. Furthermore, surface area fixings might include grinding or sculpting away damaged locations prior to using a brand-new concrete layer. Reliable surface area preparation is important to the success of any kind of concrete fixing or resurfacing task. It is additionally advisable to inspect the concrete periodically for fractures or surface damage.